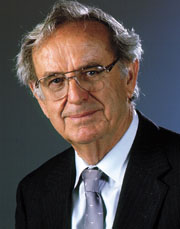

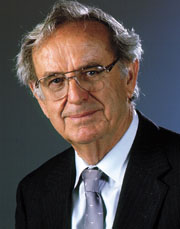

The field of irrigation lost one of its premier contributors in January when industry pioneer Edwin J. Hunter passed away in San Diego at the age of 80.

A successful inventor and businessman, Hunter was perhaps best known as the founder of Hunter Industries, which he helped take from inception in 1981 to its position today as one of the world's leading manufacturers of irrigation equipment for turf and landscape.

Although closely associated with the company that bears his name, Hunter had a long and distinguished career that extended back many years prior to the founding of Hunter Industries. In all, his career in manufacturing and the development of landscape irrigation products spanned nearly half a century and he held more than 150 U.S. patents for turf and landscape irrigation products, with many of those still applicable today.

The

Early Years.

The

Early Years.Hunter was born on June 12, 1917 in Santa Cruz, California. When he was three, his family relocated to Riverside, where he attended school and first entered the world of business, working for his father at Riverside Foundry producing bronze and gray iron castings.

In 1937, the family business, now named Hunter Engineering Co., began producing machinery and developing manufacturing processes for Venetian blind window coverings, with Ed handling the introduction of new production and assembly techniques. In the first of his many patents, Ed designed and patented roll-form machinery used to make flexible aluminum blinds. Prior to this, all window blinds had been made from wood.

During World War II, Hunter Engineering immersed itself into the war effort by producing tooling for aircraft parts and machinery tools. In 1944, the firm merged with Douglas Machine Company, changed its name to Hunter-Douglas, and went on to become one of the world's largest suppliers of window coverings and home decor accessories.

In 1952, Ed turned his inventive abilities towards the irrigation industry. He had been experimenting with the use of a tensiometer-based moisture sensor to automatically control irrigation and decided to extend this hobby into a full-time career by launching Moist-O-Matic Co.

At that time, all sprinkler heads were constructed of brass. But, Hunter foresaw the durability, economy, versatility and precision of plastics at a time when the material was on the technological fringe of development. He pioneered the use of thermoplastics for the manufacture of irrigation equipment, developing multi-station controllers and valves, along with plastic pop-up sprinklers with gear-driven rotary mechanisms. The latter was yet another Hunter innovation, replacing the standard impact drive and providing a sprinkler that isolated its moving parts from water as much as possible. Many of these products were revolutionary then, but remain the industry standard today.

In

1962, a Minneapolis-based lawn equipment firm, The Toro Company, saw the growing

market for affordable landscape irrigation products and offered to purchase

Moist-O-Matic. Ed agreed to stay on as director of design and development and in

his time at the company introduced such popular irrigation system components as

plastic valves, valve-in-head golf course sprinklers, hydraulic and electric

controllers and the stream rotor.

In

1962, a Minneapolis-based lawn equipment firm, The Toro Company, saw the growing

market for affordable landscape irrigation products and offered to purchase

Moist-O-Matic. Ed agreed to stay on as director of design and development and in

his time at the company introduced such popular irrigation system components as

plastic valves, valve-in-head golf course sprinklers, hydraulic and electric

controllers and the stream rotor.

In 1981, after 20 years with Toro, the company encouraged Ed to retire. Saying he was "too young to retire, too old to switch careers," he joined with his three children and staked his financial security on the founding of a new irrigation company, Hunter Industries.

With a portfolio of new ideas and designs, Ed's first goal was to develop a superior rotary sprinkler for the residential and commercial market. The product, initially known as the Series 75, was released in 1982 and became an instant success. It was renamed the PGP and soon became the best-selling rotary sprinkler in the history of the industry (a position it still maintains today). Its immediate success lead to the development of a complete line of gear-driven rotors for virtually all types of applications, as well as the production of other products - controllers, valves, sprays, accessories - that together comprise a complete irrigation system.

Hunter Industries now boasts a workforce of nearly 1,000 employees at its San Marcos, California headquarters and a second production facility in Cary, North Carolina. To date, more than 50 million Hunter rotors have been installed at landscapes around the world.

A former employer once described Ed Hunter as "possessing the rare creative abilities of a true inventor and the commercial instincts of an entrepreneur." No doubt, he combined those traits to perfection in leaving a distinct mark on the world and will truly be missed by all those whose lives he touched. The legacy he leaves was perhaps best summed up by his son, Richard, who continues to preside over Hunter Industries, the company into which Ed poured his heart and soul:

"My father was so future-oriented, he often considered some of his inventions obsolete before they were even marketed. I think the irrigation industry was lucky that is where he chose to apply his talents."